Understanding the Purpose of a Spreader Bar

A spreader bar is a type of rigging tool commonly used in lifting operations to distribute the load evenly across multiple points. It’s an essential component in industries such as construction, shipping, logistics, and manufacturing. The core function of a spreader bar is to reduce the stress on lifting slings and the load itself by keeping the slings at a fixed distance. This ensures safe and stable lifting, especially for long or awkwardly shaped loads.

Spreader bars are frequently confused with lifting beams, but there’s a critical difference. While lifting beams bear the entire weight of the load through bending, spreader bars transmit the load through compression, which makes them more efficient for heavier and more symmetrical lifts. Understanding this subtle yet vital difference is key to choosing the right equipment for safe lifting operations.

How a Spreader Bar Works in Real-World Applications

At its most basic, a spreader bar consists of a long beam — usually made of steel or aluminum — with lifting lugs or shackles on both ends. These connect to slings that attach to the load being lifted. The top of the bar is then attached to the crane hook via another sling or hook. When the crane lifts the spreader bar, the slings on either side pull vertically rather than at an angle, which reduces inward forces and potential damage to the load.

In practice, spreader bars are indispensable for tasks like:

- Lifting steel beams and trusses in construction

- Transporting fragile or long items like glass panels, wind turbine blades, or pipelines

- Offshore oil and gas rig installations

- Large container loading and unloading in ports

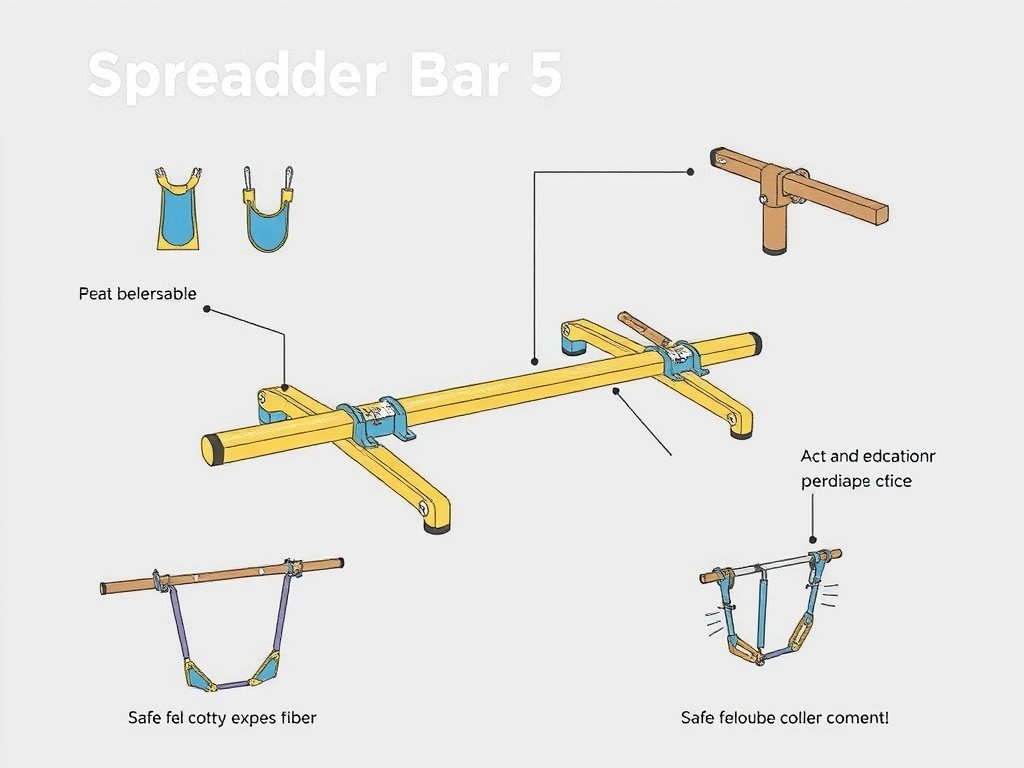

Key Components of a Spreader Bar System

A spreader bar system may seem simple at first glance, but it comprises several engineered components working in harmony. These include:

- Main Beam: The core structure that bears compressive forces.

- End Fittings: Usually shackles or hooks that connect to slings.

- Upper Rigging: A set of slings or chains that connect the bar to the crane.

- Lower Rigging: The slings that attach to the load.

Depending on the design, additional stabilizers or adjustable lugs may be included to accommodate varied loads.

Benefits of Using a Spreader Bar

The advantages of using a spreader bar extend far beyond just load distribution. It contributes significantly to safety, efficiency, and cost-effectiveness in industrial lifting. Here are some compelling benefits:

- Improved Load Stability: Even weight distribution minimizes swinging or tilting.

- Reduced Sling Stress: Prevents sling damage by maintaining a vertical lifting angle.

- Load Protection: Particularly important when lifting delicate, long, or flexible materials.

- Versatility: Adjustable models can be configured for different lengths and weights.

Industries that regularly deal with large, bulky, or fragile items benefit immensely from these improvements in safety and precision.

Common Types of Spreader Bars

Choosing the right type of spreader bar is crucial depending on the application. The most common types include:

Fixed Spreader Bar

This non-adjustable model has a set length and is ideal for repetitive lifting tasks where the dimensions of the load remain constant.

Adjustable Spreader Bar

This type allows operators to change the length of the bar, making it suitable for varied or non-standard load sizes.

Modular Spreader Bar

Constructed from separate components that can be assembled in different configurations, modular bars offer both flexibility and high load capacity.

Telescopic Spreader Bar

These can be extended or contracted like a telescope, offering adjustability without the need for multiple parts.

Applications in Construction and Engineering

In construction, spreader bars are essential for lifting prefabricated concrete walls, steel frames, and bridge segments. Engineering projects often involve materials that are both heavy and delicate, such as precast beams or turbine parts. Using a spreader bar ensures the integrity of these materials while allowing for precision placement.

Additionally, construction companies increasingly use spreader bars in tight urban environments where stability and control are paramount. A load that tilts or swings even slightly could cause significant structural damage or injury.

Why Spreader Bars Are Crucial in Offshore Industries

In offshore environments — such as oil platforms or subsea installations — conditions are more hazardous and lifting loads are often complex in shape. Spreader bars are used extensively to:

- Manage large modular structures

- Handle underwater piping and risers

- Safely load heavy equipment onto floating vessels

The unpredictable nature of ocean currents and limited maneuvering space on rigs makes spreader bars a necessity for safety and control.

Design Standards and Safety Regulations

Spreader bars are subject to strict international standards and regulations. Organizations such as ASME (American Society of Mechanical Engineers) and LOLER (Lifting Operations and Lifting Equipment Regulations) outline essential design, inspection, and operational protocols.

Table 1: Key Safety Guidelines

| Regulation Body | Key Focus Areas |

| ASME B30.20 | Design and use of below-the-hook devices |

| OSHA 1926.251 | General rigging and lifting safety |

| LOLER (UK) | Routine inspections and safe operation |

Using non-compliant equipment can result in catastrophic failures, fines, or operational shutdowns.

Spreader Bar vs. Lifting Beam: Key Differences

Though often confused, spreader bars and lifting beams serve different mechanical purposes. Here’s a comparison:

Table 2: Spreader Bar vs. Lifting Beam

| Feature | Spreader Bar | Lifting Beam |

| Load Type | Axially compressed | Bending load |

| Application Focus | Even load distribution | Load held closer together |

| Sling Angle | Vertical or near vertical | Angled |

| Best Use Case | Long/fragile loads | Center-heavy or compact loads |

This distinction is vital in ensuring the right tool is used for the job.

Proper Maintenance and Inspection Guidelines

Like any lifting tool, spreader bars must be regularly maintained to ensure optimal performance. Neglecting routine inspections can compromise both safety and equipment longevity.

Essential maintenance practices include:

- Checking for corrosion, cracks, or deformation

- Inspecting welds and connection points

- Verifying load limits and tag readability

- Lubricating moving or adjustable parts (in telescopic models)

Periodic third-party inspections are also recommended, particularly in industries with heavy-duty usage.

Cost Considerations and ROI

Spreader bars are an investment, but one that yields significant return when safety and efficiency are prioritized. The price of a spreader bar varies based on type, capacity, and customization but generally falls between $500 to $5,000+.

While initial costs might seem high, consider the savings in:

- Reduced damaged goods

- Improved labor efficiency

- Fewer safety incidents

- Regulatory compliance

These benefits easily outweigh the upfront cost in long-term operations.

Customized Solutions for Specific Industries

Many manufacturers now offer custom-built spreader bars tailored to industry-specific needs. For example:

- Aerospace: Bars designed to support fuselage or wing sections.

- Wind Energy: Configurations for long, fragile turbine blades.

- Nuclear Industry: Certified bars for radioactive or sensitive equipment.

Custom options include adjustable pin holes, specialized coatings, or corrosion-resistant materials for marine use.

Emerging Technologies in Lifting Equipment

Technology is transforming the humble spreader bar. Modern innovations include:

- Load-sensing spreader bars with embedded strain gauges

- Smart rigging systems integrated with crane software

- Remote-controlled modular configurations

These innovations help operators monitor real-time loads, prevent overloading, and improve precision — critical for high-risk sectors like aerospace or deep-sea installation.

Training and Certification: A Must for Operators

It’s not enough to have the right tools; operators must be trained to use them properly. Certification ensures that workers understand:

- Proper rigging techniques

- Load chart interpretation

- Emergency response protocols

- Equipment inspection procedures

Training also enhances workplace culture, reducing the likelihood of costly accidents.

Conclusion: Why Spreader Bars Are Indispensable Today

The spreader bar remains a cornerstone of safe lifting practices in modern industry. From high-rise construction to offshore rigs and renewable energy projects, this tool ensures loads are lifted with precision, safety, and minimal risk. With evolving technology, customization, and strict safety standards, the spreader bar is no longer just a steel bar — it’s a smart solution engineered for modern challenges. Investing in quality spreader bars, regular inspections, and proper training can significantly enhance operational efficiency and safety outcomes.

FAQs: Related to Spreader Bars

Q1: Can I use a lifting beam instead of a spreader bar?

Not necessarily. While both lift loads, they distribute weight differently. A spreader bar uses compression and is better for long or fragile loads, whereas a lifting beam bears load through bending.

Q2: How often should a spreader bar be inspected?

Regular visual inspections should be done before each use, with more detailed professional inspections recommended at least annually or based on usage frequency.

Q3: Are there weight limits for spreader bars?

Yes, each spreader bar comes with a rated capacity. Exceeding this limit can lead to catastrophic failure. Always refer to the manufacturer’s specifications.