Prizmatem is a modern concept that processes complex information and presents it from multiple perspectives, helping users see data in clearer, structured ways.

Prizmatem combines the ideas of a prism and systemic analysis, offering a framework to refract complex datasets into manageable insights. Used in emerging tech and data visualization fields, Prizmatem emphasizes clarity, adaptability, and innovation. By breaking down intricate information into structured perspectives, this concept supports better decision-making and design across multiple industries.

Introduction to Prizmatemquartist

Prizmatem quartist is a new-age concept that combines the advanced science of Prizmatem and the creative innovation of Quartist. It reshapes how materials, light, and design interact. From high-end cameras, architectural glass, and medical instruments to advanced construction, the role of Prizmatem quartist is expanding. This hybrid innovation takes cues from both modern optics and structural design, creating smart, efficient, and visually powerful materials.

At its core, Prizmatemquartist focuses on combining optical-grade material and artistic design. It merges synthetic, prism-like composite technologies with creative visual frameworks. This powerful blend allows light to pass, bend, and reflect in ways that enhance performance, usability, and aesthetics.

The Science Behind Prizmatem quartist

The material base of Prizmatemquartist includes silica-based micro-prisms and a polymeric matrix that acts as the foundational support. These core elements are engineered through casting/molding techniques, followed by UV curing and surface treatments to increase reliability.

The use of a UV-cured methacrylate matrix improves performance by enabling impact resistance, durability, and temperature stability. Light is controlled precisely using micro-scale prism technology, offering superior clarity and strength.

High Refractive Index and Light Optimization

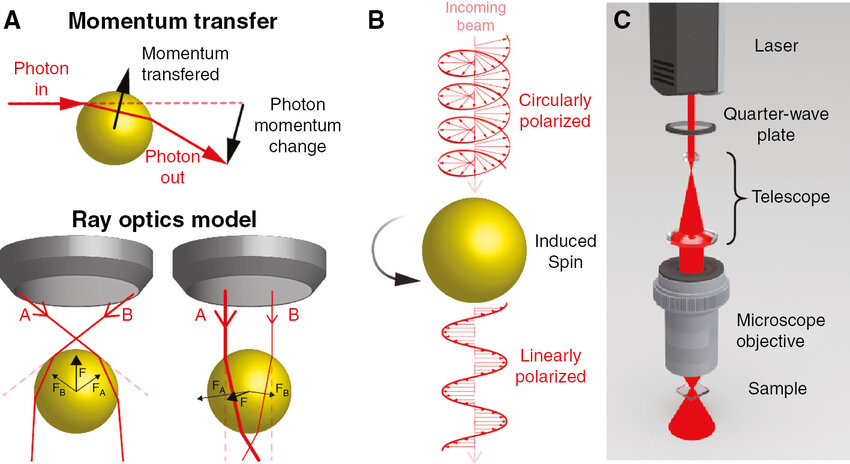

What makes this material unique is its high refractive index, which allows better manipulation of light. The structure is designed to optimize light transmission for demanding applications such as telescopic lenses or surgical devices.

This feature is critical in devices requiring light clarity, brightness, and directional control. Unlike older technologies, Prizmatemquartist efficiently reduces distortions while maximizing light focus.

Applications in Diverse Industries

Prizmatemquartist is being applied in multiple high-end industries. These include:

- High-end cameras, improving lens sharpness

- Architectural glass, with self-cleaning and light-bending properties

- Medical instruments, with better optical accuracy

- Advanced optics in security systems

- Wearables with adaptive lighting

The dual strength of material engineering and design offers real-world solutions that traditional materials can’t match.

Impact Resistance and Environmental Resilience

Designed to withstand harsh conditions, Prizmatemquartist offers strong impact resistance. This makes it reliable in applications that involve physical pressure, movement, or shock.

It also shows excellent durability and environmental resilience, making it a top pick for outdoor use, construction, and space-grade materials. Even under intense temperature changes, the structure remains stable and effective.

How Prizmatem quartist Is Manufactured

The production process includes the casting/molding of a synthetic, prism-like composite. This is followed by UV curing, which hardens the material uniformly and quickly.

Once solidified, advanced surface treatments are applied to boost appearance, friction control, and environmental protection. Nanofillers may be added for enhanced performance.

| Manufacturing Step | Function |

| Casting & Molding | Shapes the composite |

| UV Curing | Solidifies material |

| Surface Treatments | Enhances surface durability |

| Nanofillers | Boosts mechanical performance |

Integration with Structural Design

The integration of Prizmatemquartist with modern optics and structural design allows architects and engineers to shape materials into innovative structures. Transparency and strength are key benefits here.

By adjusting the angle of silica-based micro-prisms, designers control the light’s path. This is used in museums, galleries, and office buildings to balance light, reduce heat, and create ambiance.

Why Designers Prefer This Material

Unlike traditional glass or plastic, this advanced composite provides the flexibility of art and the science of physics. Artists and engineers can create bold designs without compromising function.

Its aesthetic value combined with temperature stability and light transmission optimization makes it attractive in visual arts and architecture. You get form and function in one smart package.

Comparing with Traditional Optical Materials

Compared to traditional optical glass or polymers, Prizmatemquartist offers:

- Better durability

- Higher impact resistance

- Precise light control

- Improved temperature stability

- Superior environmental resilience

These properties place it in a league of its own. Old materials lack the customizable flexibility and strength offered here.

The Artistic Side of Prizmatem quartist

While based in science, this innovation includes a strong artistic element. Designers use the unique properties of prism-like composites to play with colors, reflections, and illusions.

This adds a new layer of interactivity in product design. From futuristic buildings to interactive art installations, its presence is growing in creative spaces.

Role in Healthcare and Medical Tools

In the medical field, accuracy and durability are everything. Prizmatemquartist improves visualization and precision in tools used for surgeries and diagnosis.

It enhances the function of medical instruments by reducing glare and improving clarity. The smooth surface also supports better hygiene and easy sterilization.

Technological Synergy and Innovation

Prizmatemquartist sits at the intersection of technology and creativity. It evolves continuously with the help of nanofillers, machine learning design models, and AI-optimized geometry for better structural use.

This opens up doors to futuristic designs and high-efficiency systems in buildings, wearables, and even spacecraft. Its journey is far from complete.

Also read this:Is vollnou8.7z for Windows About wtonecap3.0.34 Bug?

Commercial and Public Use Cases

From fashion runways to smart windows, Prizmatemquartist has reached public spaces. Museums use it to shape how light interacts with exhibits. Tech companies install smart walls made of it.

This versatility shows how far the material can go. It meets commercial needs while offering high-end quality.

Is It Sustainable and Eco-Friendly?

Many of its components are recyclable. The process of UV curing uses less energy than conventional baking methods. The synthetic composite also reduces waste when customized properly.

Though not 100% green, it’s significantly more efficient and low-waste than traditional manufacturing materials.

Conclusion: A Smart Material for a Smart World

Prizmatem quartist represents the future of intelligent design and advanced optics. It unites art, science, and practicality into one composite solution. With its high-tech core of optical-grade material, UV-cured methacrylate matrix, and high refractive index, it delivers unmatched versatility.

Whether used in high-end cameras, architectural glass, or medical instruments, it stands for a smarter, more aesthetic future. It is a symbol of innovation where creativity meets material science.

FAQs

What is Prizmatem?

Prizmatem is a term describing a data innovation concept that simplifies complex information into multi-faceted, clear perspectives.

Why is Prizmatem important in technology?

It helps transform overwhelming datasets into structured formats, making analysis and decision-making easier.

How does Prizmatem work?

Much like a prism, it refracts complex data into multiple perspectives, each showing useful insights.

Is there an official Prizmatem website?

No, there does not appear to be a website using that exact domain; the term is mainly used in tech and innovation discussions.

What industries can benefit from Prizmatem?

Sectors like data analytics, visualization, AI development, and system design can apply its principles.

Does Prizmatem involve AI?

Yes, this platform can integrate AI tools to analyze and restructure large datasets effectively.

Is Prizmatem a product or a concept?

Currently, it is more of a conceptual framework, though some groups experiment with applying it in tech projects.

How is Prizmatem different from traditional visualization tools?

Unlike basic visualization tools, it emphasizes multi-perspective breakdowns rather than one-dimensional representations.

Can businesses implement Prizmatem methods?

Yes, companies focusing on big data, UX design, and information management can adopt its approaches.

What does the name Prizmatem mean?

The name combines “prism” and “system” (or “atem”), symbolizing the refraction of data into simpler, multi-faceted insights.

fore more info:londontechinsights.co.uk